Subscribe Newsletter

A quick message to TECHNID

Client Speaks

Lorem Ipsum is simply dummy text of the printing and ty . . .

Lorem Ipsum is simply dummy text of the printing and ty . . .

Lorem Ipsum is simply dummy text of the printing and ty . . .

RPSB Module is a Safety Class 1A system which has gone through all the requisite tests before accepting it as suitable for extremely critical reactor operations. The tests conducted successfully on the RPSB Module alone and in RPSB Channel are as follows:-

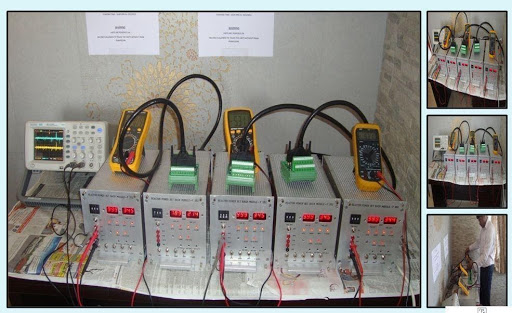

1. INITIAL TESTS and BURN-IN TEST

- Functional Test – 1 / FT – 1 which is pre-Burn In and it tests the complete functionality of the Module as per the Approved Test & Acceptance Procedure developed by TECHNID SOLUTIONs and thoroughly reviewed, verified and approved by the client(s).

- BURN-IN which is a 100 hours POWER ON of the Module to test the general durability of the electronic components used in the module, PCB Wiring and Complex Module Wiring health and Monitoring the module temperature through out the operation.

- Functional Test – 2 / FT – 2 which is post-Burn In and it tests the complete functionality of the Module as per the Approved Test & Acceptance Procedure developed by TECHNID SOLUTIONs and thoroughly reviewed, verified and approved by the client(s).

Before and After BURN-IN tests, all the analog outputs were found to be well within limits.The digital outputs and all the field contacts generated from the module were monitored and found to be correct before and after the completion of BURN-IN tests.

2. CLIMATIC TESTS

With support of TECHNID SOLUTIONS, following tests had been conducted at HYDERABAD:-

A set of four tests have been conducted successfully under climatic tests which comprise of both dry and damp environment tests. The tests conducted were as follows:

- DRY COLD CYCLE TEST OF RPSB Module as per PFBR/60000/SP/1013, Rev.3.0.

- DRY HEAT CYCLE TEST OF RPSB Module as per PFBR/60000/SP/1013, Rev.3.0.

- TEMPERATURE CYCLE TEST OF RPSB Module as per PFBR/60000/SP/1013, Rev.3.0.

- DAMP HEAT CYCLE TEST OF RPSB Module as per PFBR/60000/SP/1013, Rev.3.0.

All the analog outputs were found to be well within limits. The digital outputs and all the field contacts generated from the module were monitored and found to be correct after the completion of the above mentioned tests.

3. SEISMIC TEST

With support of TECHNID SOLUTIONS, following tests had been conducted at HYDERABAD:-

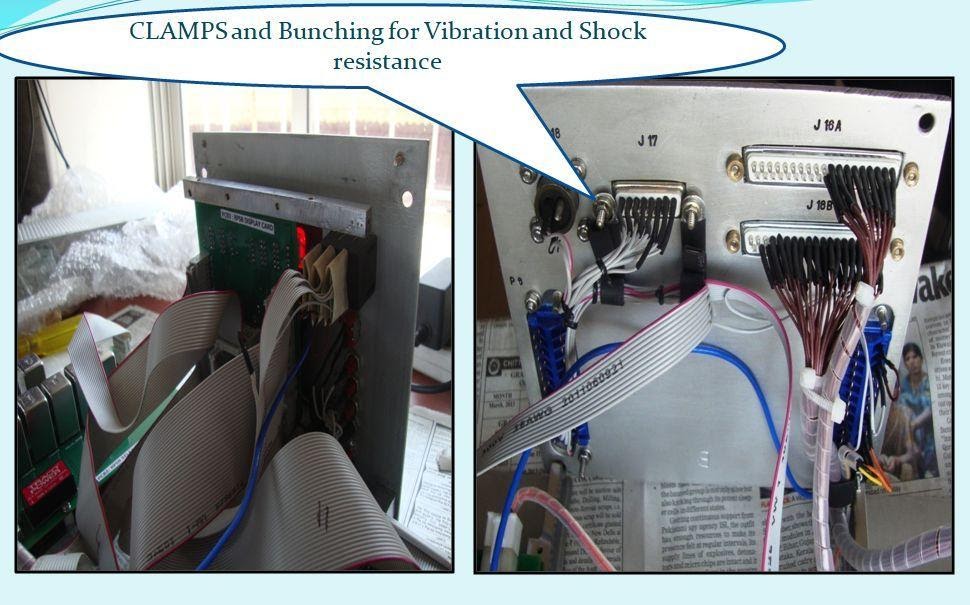

- A set of tests have been conducted on all the 3 axes i.e. X, Y and Z axes successfully as per PFBR standard- PFBR 26030 DN 10000 RB.

- On each of the 3 axes, 5 OBEs are followed by 1 SSE conducted as per FRS of LCC in Control Building.

After the Seismic test the RPSB Channel consisting of the RPSB Module was examined and found to be free from mechanical damages no loosening of parts was observed. The unit was then found to be meeting the Post Seismic Functional Test requirement.

4. EMI / EMC TESTS

Following tests with support of TECHNID SOLUTIONS had been conducted at SAMEER CHENNAI as per IP.No. PFBR/60000/SP/1014, Rev.0 and the RPSB Channel along with the Module passed the Safety Class A criteria in all:

- Conducted Emission Test as per CISPR 11, CLASS A, GROUP1 (2004-06) on DC I/P P/S.

- Radiated Emission Test as per CISPR 11, CLASS A, GROUP1 (2004-06).

- Electrostatic Discharge Test as per IEC 61000-4-2

- Radiated Susceptibility Test as per IEC 61000-4-3

- Electrical Fast Transient test as per IEC 61000-4-4 on DC I/P P/S

- Surge Test as per IEC 61000-4-5 on DC I/P P/S

- Conducted RF Test as per IEC 61000-4-5 on DC I/P P/S

- Ring Wave & Damped Oscillatory Wave Test as per IEC 61000-4-12 on DC I/P P/S.

Detailed Manuals Available.

THIS HAS BEEN DEVELOPED HYDERABAD FOR NUCLEAR INSTRUMENTATION TYPE REACTOR SAFETY CLASS 1A APPLICATION.

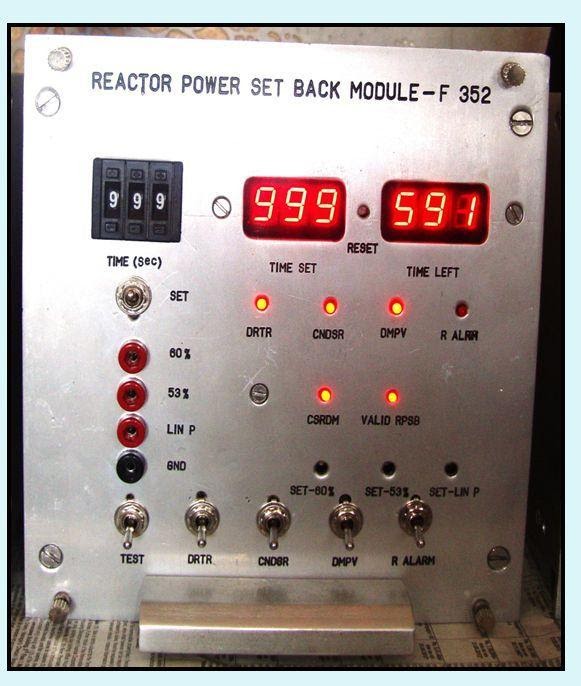

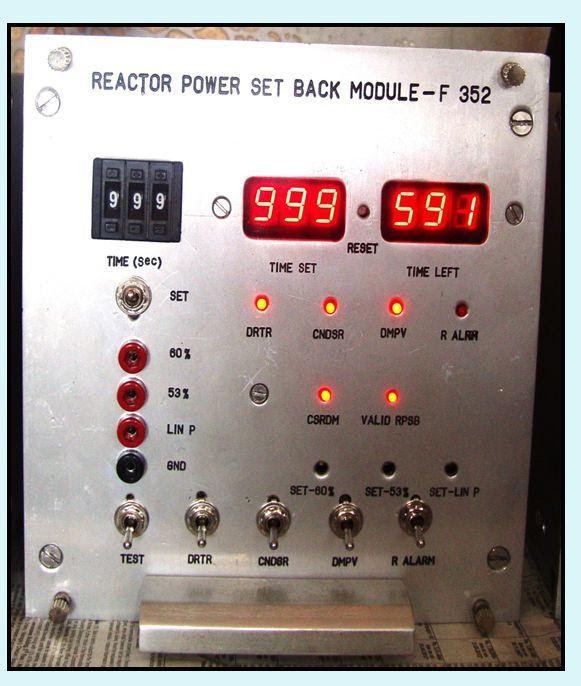

- It also enables or disables the Control and Safety Rod Drive Mechanism (CSRDM) operation used for driving control rods for addition of positive or negative reactivity during Reactor Power Set Back Operation.

- Module generates a complex sequence of contact outputs during RPSB operation, displays the Total RPSB Operation Time and the Remaining RPSB Operation Time in analog and digital form, outputs internally generated important Threshold Parameters and Linear Neutron Power signal for monitoring and remote transfer purpose.

- All the important Analog Parameters generated, Digital Delays incorporated in the design are completely settable for providing flexibility required during commissioning and operation.

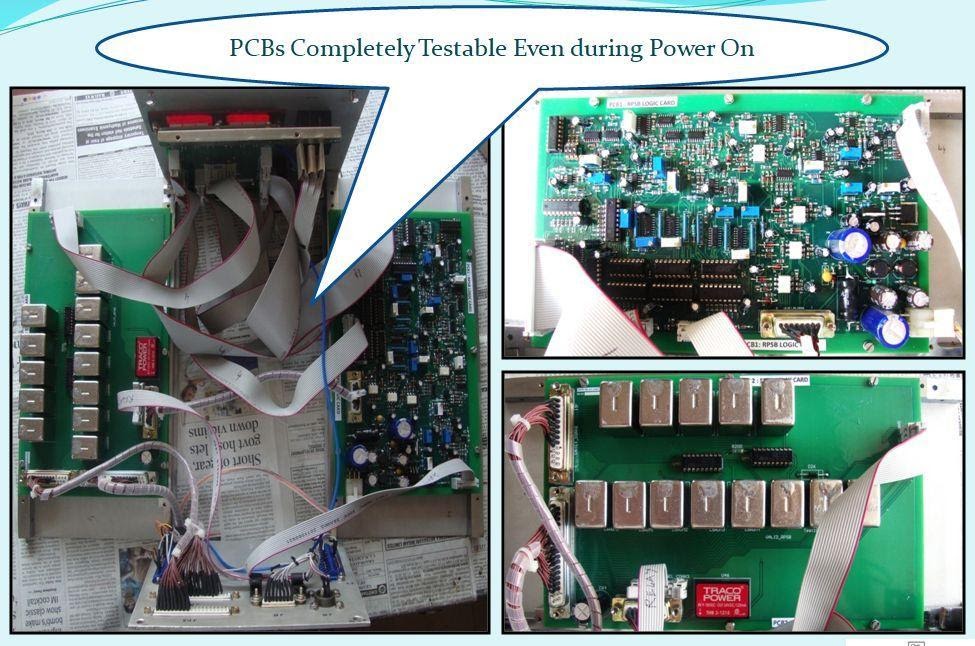

- RPSB Module has Built In Test Feature i.e. is completely testable in the Test Mode w/o any external components.

- Accuracy of all the Analog and Digital Outputs is within ±1% of the Full Scale Output. Entire circuit design is FAIL-SAFE against Power Supply Failure and Logic Failure.

- Conducted Emission Test as per CISPR 11, CLASS A, GROUP1 (2004-06) on DC I/P P/S.

- Radiated Emission Test as per CISPR 11, CLASS A, GROUP1 (2004-06).

- Electrostatic Discharge Test as per IEC 61000-4-2

- Radiated Susceptibility Test as per IEC 61000-4-3

- Electrical Fast Transient test as per IEC 61000-4-4 on DC I/P P/S

- Surge Test as per IEC 61000-4-5 on DC I/P P/S

- Conducted RF Test as per IEC 61000-4-5 on DC I/P P/S

- Ring Wave & Damped Oscillatory Wave Test as per IEC 61000-4-12 on DC I/P P/S.